Komatsu PC200-6 hydraulic crawler excavator sometimes works weekly and moves slowly. We think the main problem is the faulty hydraulic system. This article mainly helps to analysis on this issue and hope that it will help.

1. Low Pressure for The Main Pump

PC200-6 excavator uses a double swash plate type axial variable displacement piston pump. normally the main pump output oil pressure over 30mpa. if the wear circumstance between the piston and the cylinder block of main pump or the wear circumstance between the top surface of the cylinder block and the valve plate exceeds the standard (the gap between the piston and the cylinder should be less than 0.02 mm, and the contact area between the top surface of the cylinder block and the valve plate should be no less than 90%), which will cause output pressure to be low. it is reflected in the mechanical working device, and the whole machine will work weakly.

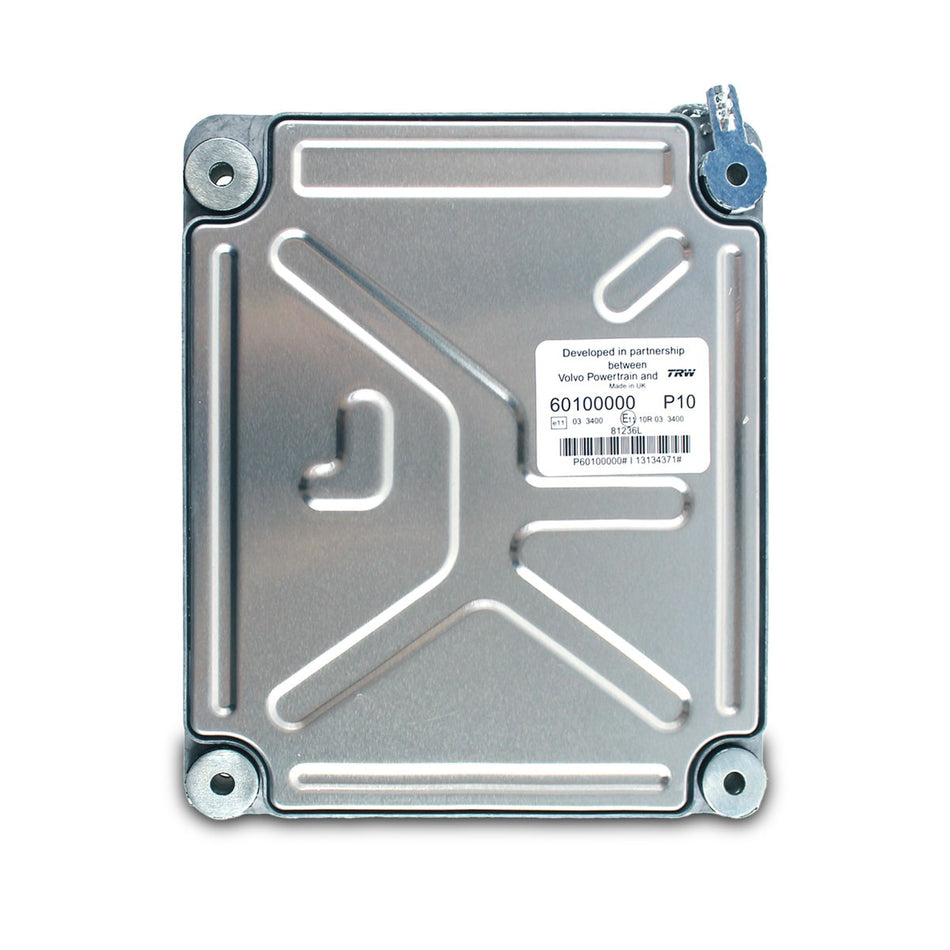

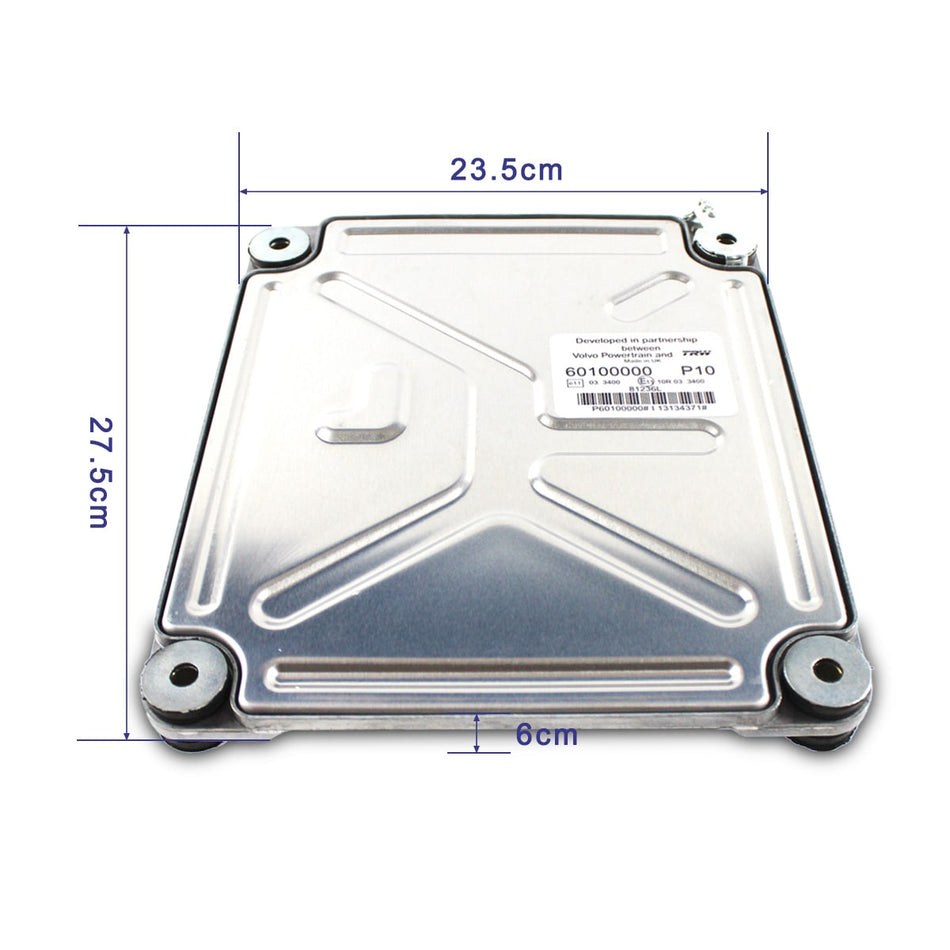

2. The Faulty of Main Pump Control Valve Group

The output of the main pump of the machine changes with the change of engine power if the main pump and the engine's power are optimally matched, and engine work in good conditions. If control valve group, which is used to regulate the main pump output flow, is in faulty, such as the PLS feedback circuit blockage, the LS valve spool stuck, the PC valve spool stuck or the PC-EPC solenoid valve coil burned, etc. The main pump will be always in a state of constant flow, and performance of the machine will be weak and slow. Similarly, if the parts like Cradle support, servo piston, and the other parts of the main pump that directly control the main pump flow change are stuck, the output flow of the main pump will not change.

3. The Slow Output for The Suction Valve Assy

Normally the suction valve Assy can reduce the output oil pressure of the main pump and stabilize it at 3.3 MPa, which is a normal control oil pressure. If the oil quality is poor and make the conical spool is not tightly closed, the output pressure of the suction valve will be lower than 3.3 MPa. At this time, no matter how to operate the joystick, the control oil pressure is always low. The movement amount of the spool on the main control valve for various working devices is too small, so that the flow rate to the working device is also small. The whole machine will be powerless.

4. Low Relief Pressure for Main Relief Valve

When the drive start the engine and leave the joystick handle to neutral gear, the hydraulic oil from main pump will be returned to oil tank through Unloading valve,and the unloading pressure is 3Mpa. If the oil is in poor quality, and the spool inside cannot be tightly closed, when the machine works, the high pressure system cannot be set; similarly if the O-ring seal which is used to prevent the connection from PLS pressure oil and oil tank is broken, the hydraulic oil will flow to oil tank directly.

6. LS Valve Faulty

The LS valve can leak some of the P15 pressure oil on the LS circuit through two small holes (slightly) on the valve body to increase the softness of the machine operation. If the O-ring seal on the valve body is damaged, the PL5 pressure oil will directly connect to the oil tank, which indirectly causes the unloading valve to open normally, causing the working devices to be weak and slow.

In short, the powerless of PC200-6 is mainly due to the poor oil quality of the hydraulic oil. Therefore, replacing the hydraulic oil filter on time (specified to be replaced every 500 hour) and paying attention to monitoring the hydraulic oil quality (viscosity, fluidity and presence or absence of suspended solids) is the key to avoiding or reducing such failures.