Excavate Machine Maintenance Hydraulic Components Excavate Frequent Fault with Noise.

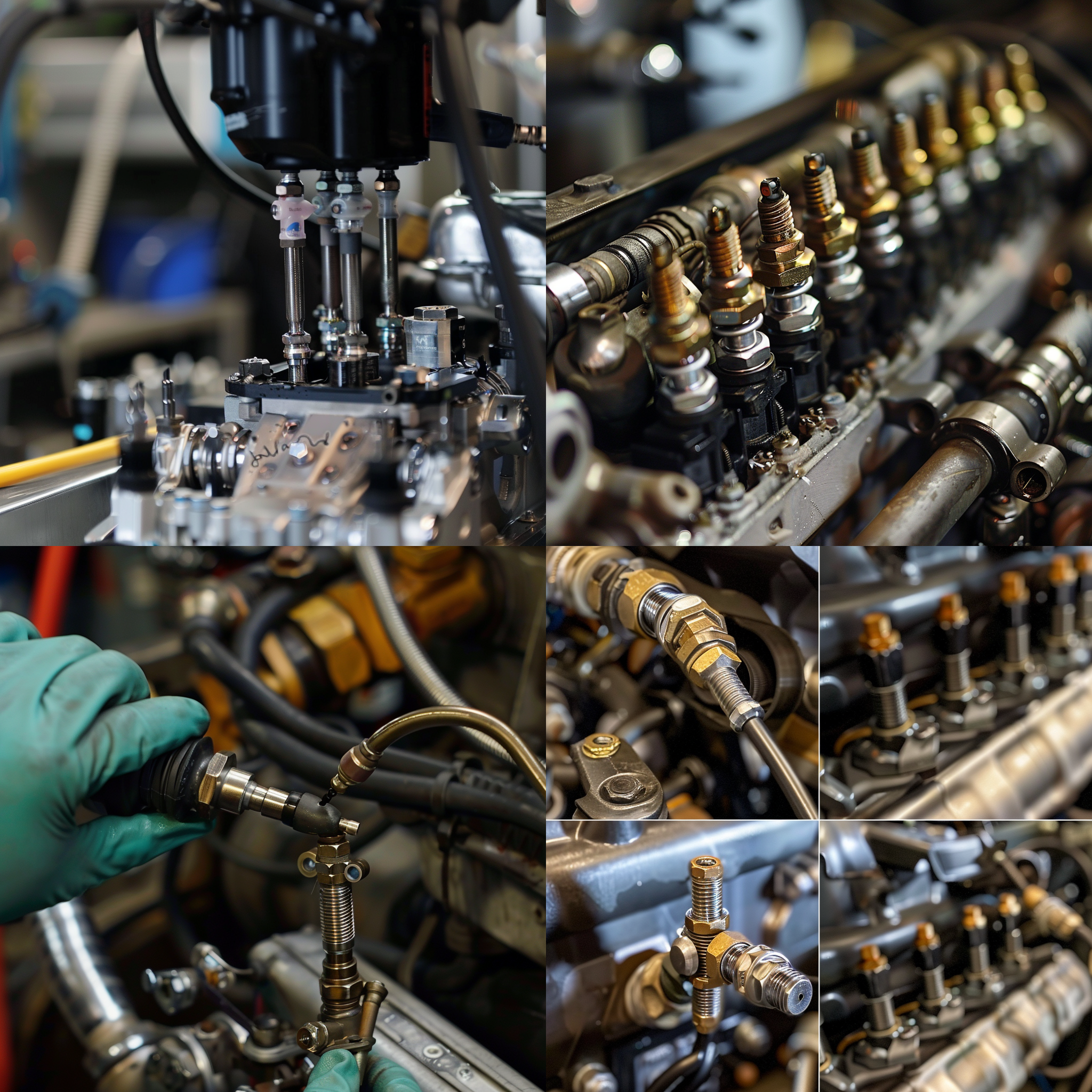

The repair of the old car repaired by the excavator is to repair the assembly, components and parts removed from the car during the repair. All the parts that can be repaired are installed back to the original car after repair.

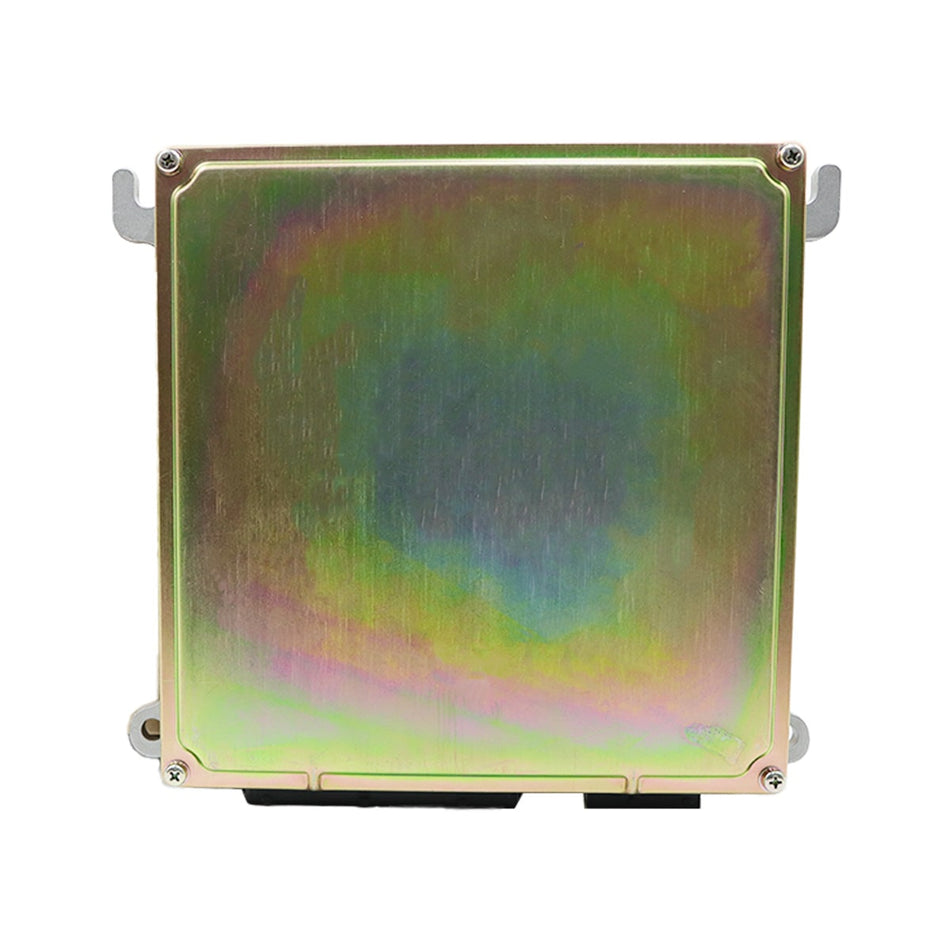

The repair work needs to be done by experienced maintainers after proper procedures are carried out and cleaned by maintainers to ensure that there is no dirt in the interior. Excavator maintenance is to replace accessories, pure maintenance accessories, according to the function of repair, maintenance and recovery, maintenance, maintenance, repair. Improve the excavator repair technology and quality, through the use of modern information technology, on the basis of one-stop maintenance and inspection, the formation of a perfect excavator repair industry service chain.

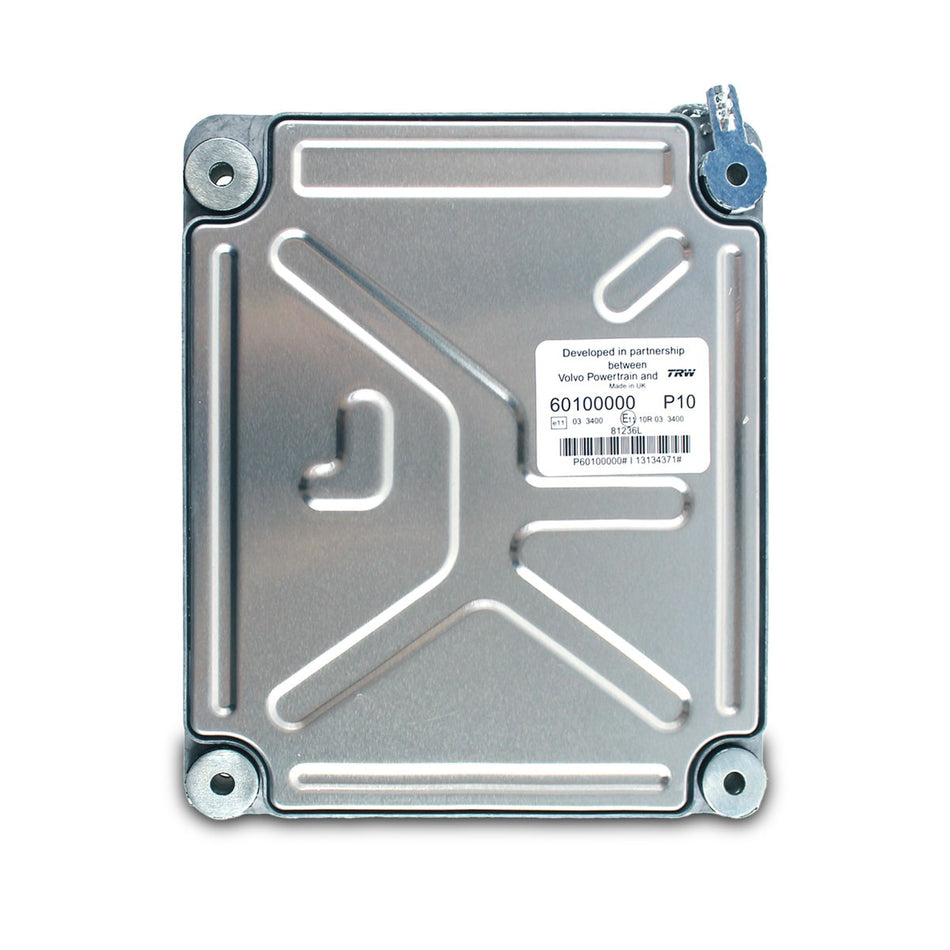

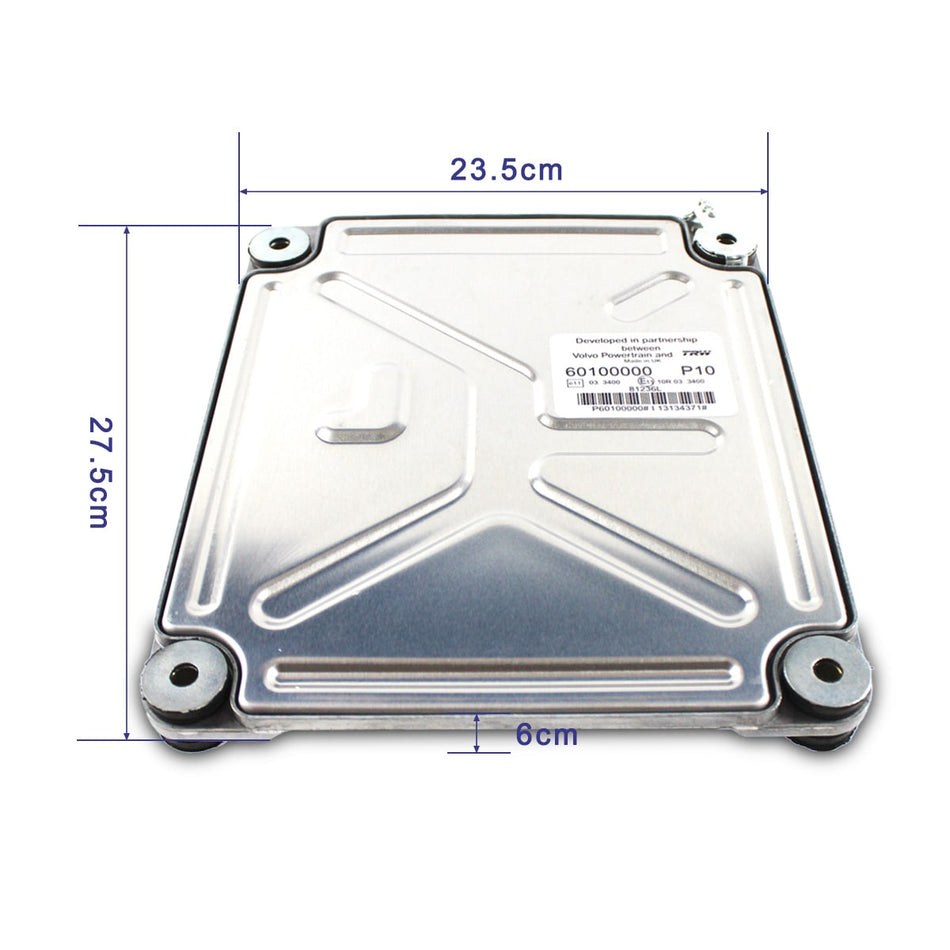

The relief valve is easy to generate high frequency Induction Heating noise, mainly due to the pilot valve performance is not stable (explanation: stable; No change), that is, the noise caused by the air vibration caused by the high frequency oscillation of the pressure in the front chamber of the pilot valve.

The main reasons are as follows:

(1) the oil is mixed with air, and the cavitation phenomenon is formed in the front cavity of the pilot valve and causes high frequency noise. The repair of the old car repaired by the excavator is to repair the assembly, components and parts removed from the car during the repair. All the parts that can be repaired are installed back to the original car after repair. The repair work needs to be done by experienced maintainers after proper procedures are carried out and cleaned by maintainers to ensure that there is no dirt in the interior. At this point, the air should be drained in time and prevent the outside air from re-entering.

(2) the needle valve in the process of use due to frequent open and excessive wear (a basic type of parts failure), so that the needle valve cone and valve seat can not close, resulting in pilot flow instability, pressure fluctuations and noise, should be repaired or replaced in time.

(3) the pilot valve due to the fatigue deformation of the spring caused by its pressure regulating function is not stable (interpretation: stable; No change), so that the pressure fluctuates greatly and causes noise, at this time should be replaced by the spring.

2. The noise of hydraulic cylinder

(1) There is air mixed with oil or hydraulic cylinder, and the air in the cylinder is not exhausted, resulting in cavitation phenomenon under high pressure and resulting in large noise.

At this point, the air must be drained in time.

(2) If the oil seal of the cylinder head is too tight or the piston rod is bent, noise will be generated due to different force during the movement. At this time, the oil seal or straightening piston rod must be replaced in time.

3. Too many dead bends or loose fixed clips can also produce vibration and noise. Therefore, in the pipeline layout should try to avoid dead bending, loose clips must be tightened in time.